3D Print on Demand

Processes Involved:

FDM 3D Printing

Resin 3D printing

Files Designs discovered online

Brief/Overview

Over the past decade there has been a growing demand for additive manufacturing services in Canberra, opening the need for more 3D printing. Since 2016, InIteration has increased the scale of our business by improving printer utilisation and output. Our suite of 3D printers needed to be capable of running multiple machines in parallel, with remote operation and monitoring for safety. To ensure our client’s experience with 3D printing is as smooth as possible.

For more information about FDM 3D printing, read our knowledge guide WHAT IS FDM/FFF - FILAMENT 3D PRINTING.

For more resin 3D printing, read PAST WORK - RESIN TABLETOP MINIATURES.

-

The many ways that a 3D printer can fail

Maintaining qualityAccounting for the unique quirks of different materials

Streamlining the process of sending print jobs from computer to printer, and computer to many printers.

Optimising 3D printer reset - ready for the next job

Timing/managing printing to minimise downtime

Designing for 3D printing

When to use a 3D printer, and when NOT to use 3D printing

Maintaining digital security and safety.

Prioritising health

Approach

Development of the InIteration 3D print farm is the result of a long history of overcoming challenges. Over our years of experience, we have worked hard to provide accurate turnaround times to meet deadlines and client demand. This has been a steady growth and boot-strapped through our entire journey. The reason InIteration can provide this quality service is because of our dedication to constant learning and improvement with each and every project.

Outcome

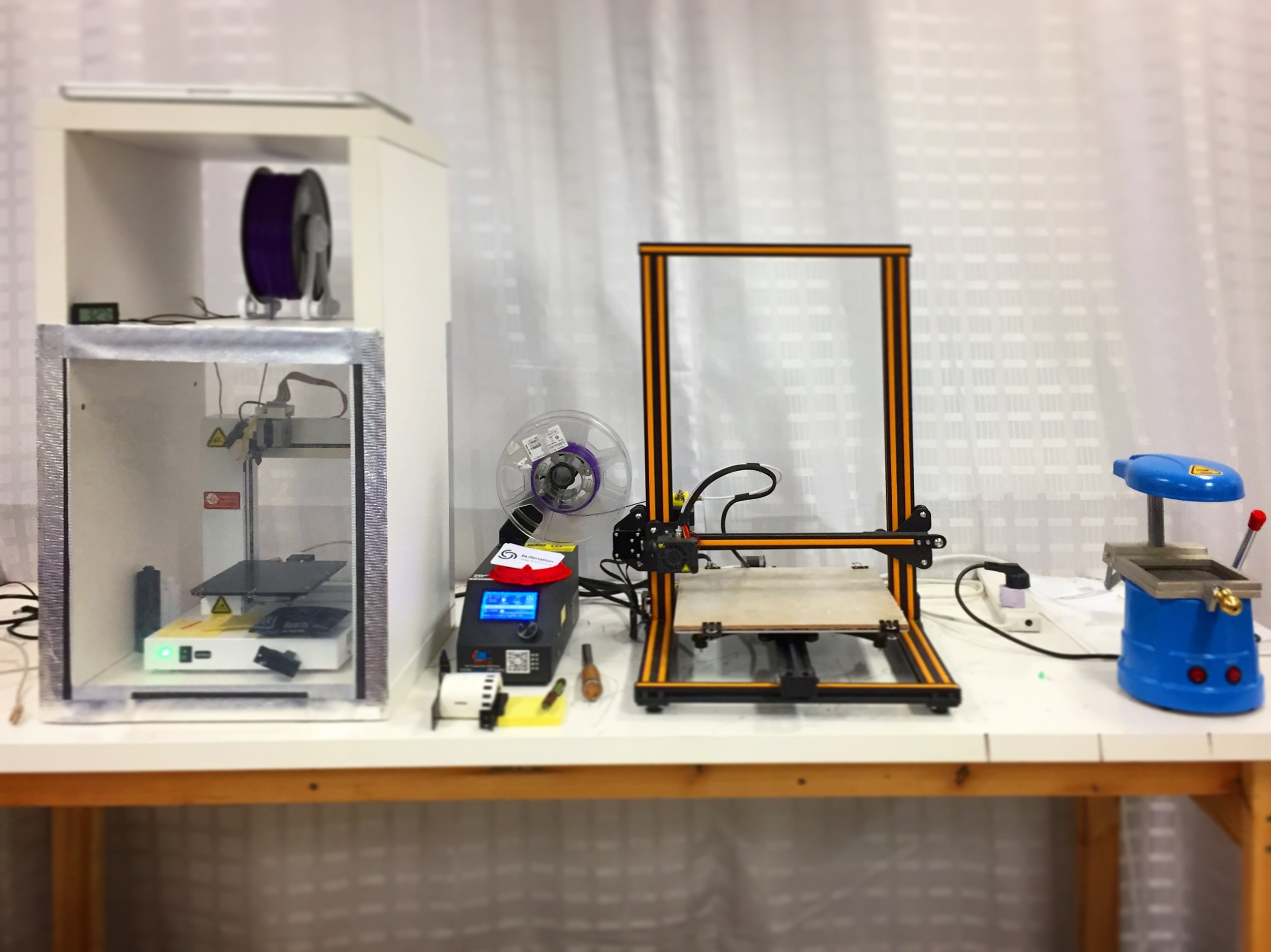

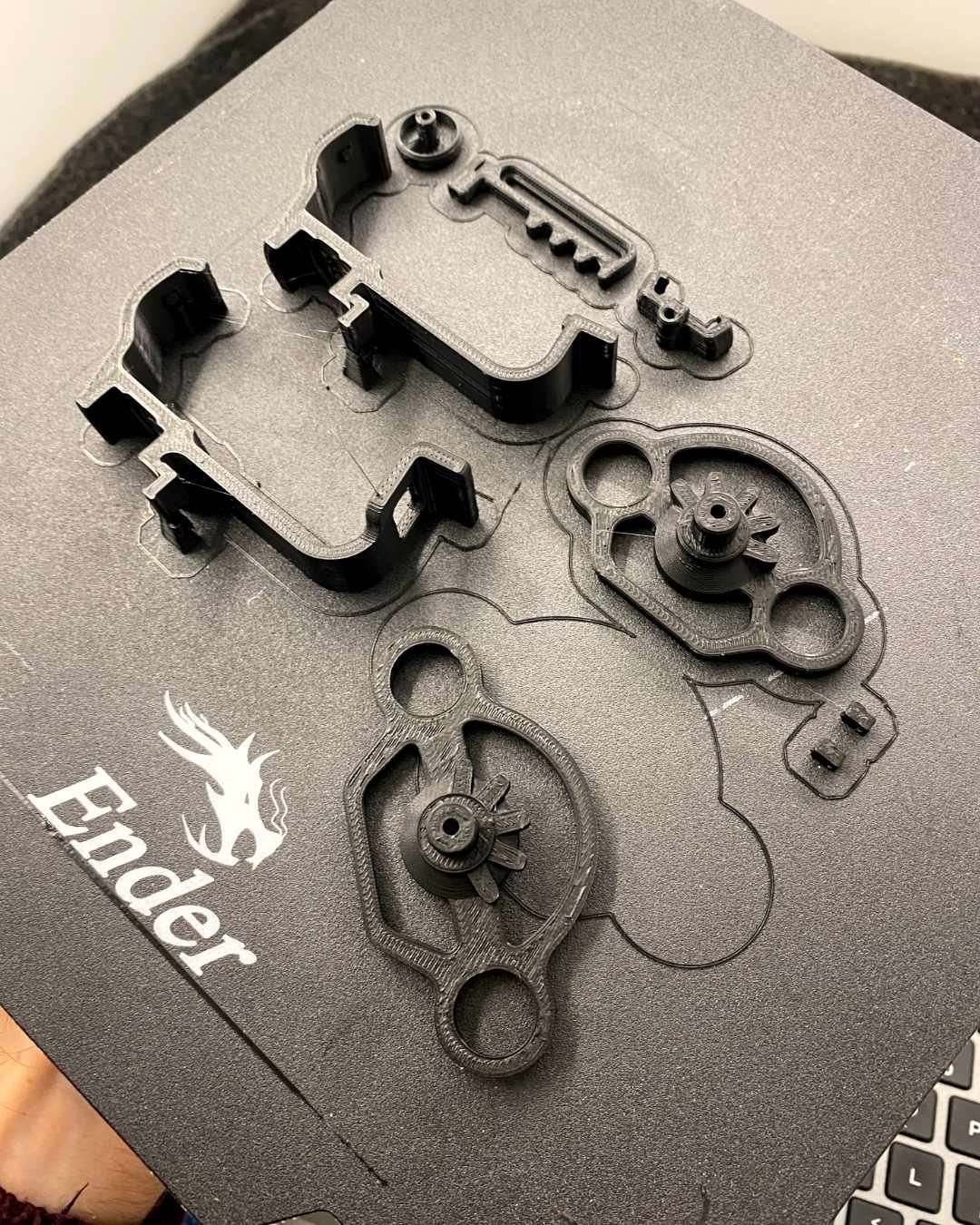

The InIteration print farm is a suite of networked 3D printers that can be operated and monitored remotely. This affords us flexibility and confidence. This is supported by secondary print hubs and fabrication partners to manage the workload. We have contingencies and the experience to adapt quickly to unexpected challenges, and blockers. E.g. print failures, down time, and changes in the design.

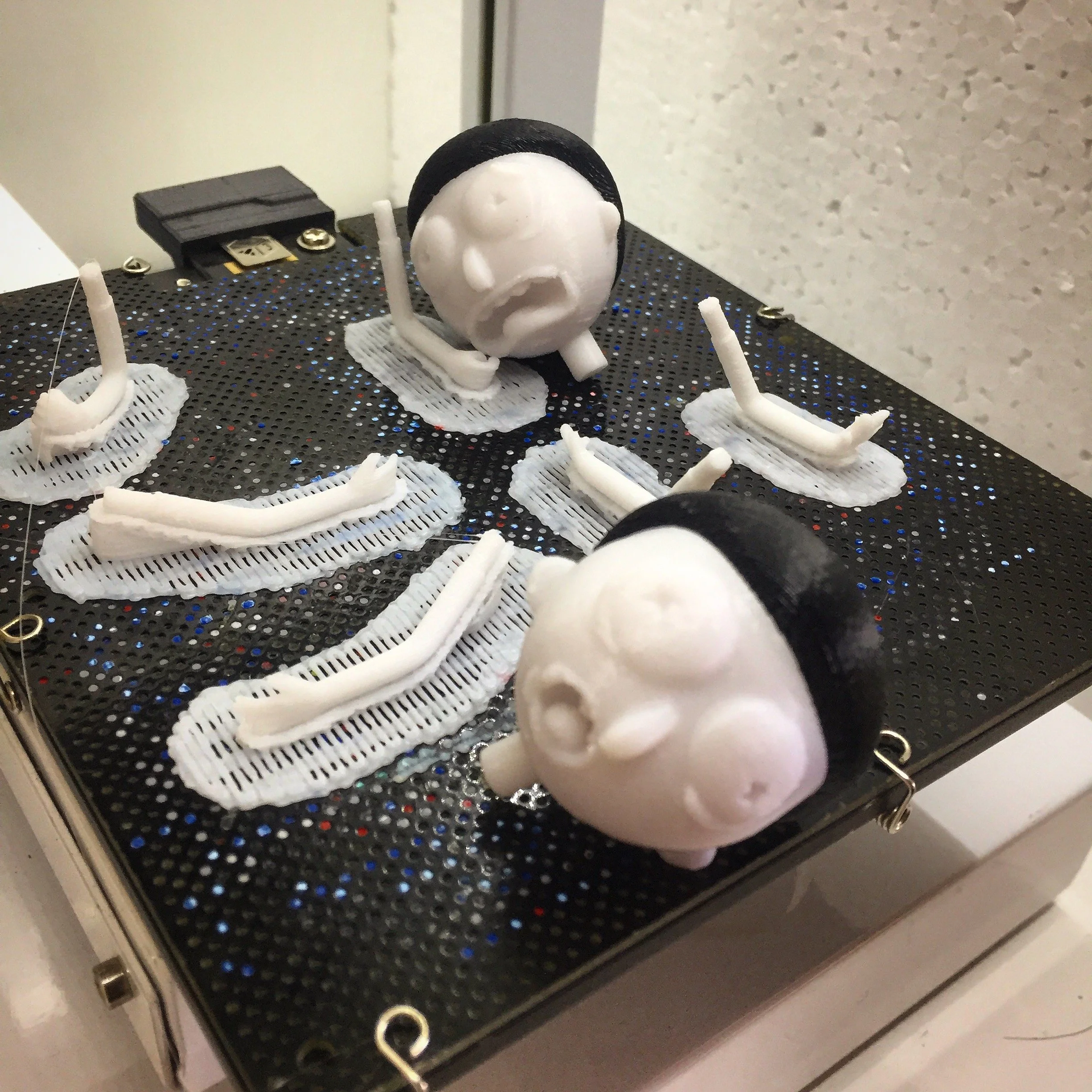

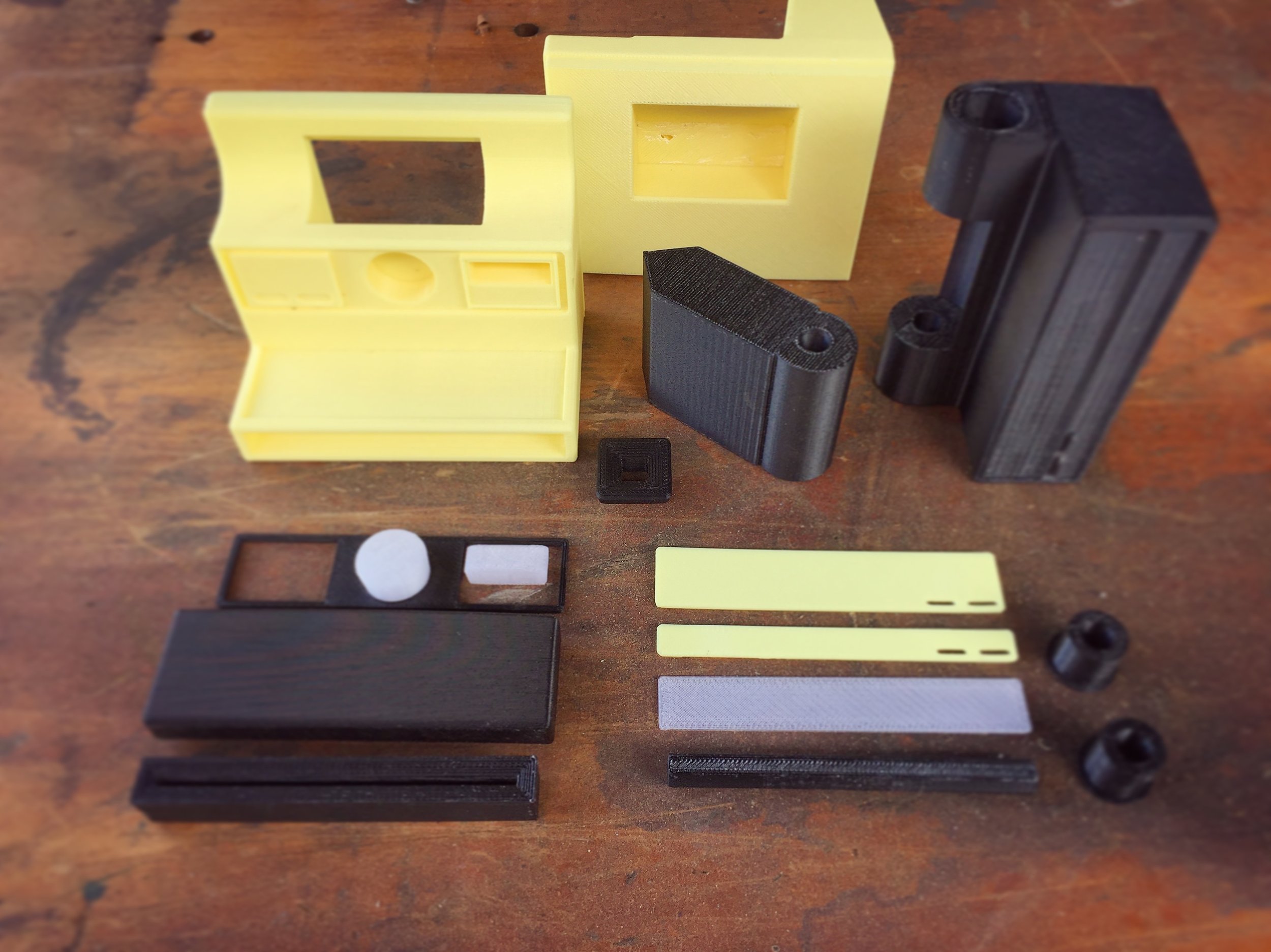

When a customer has an idea, we help make it reality. Often these are designs found online, but we also help customers search for existing work and identify alternatives. We provide feedback on designs and its printability. Clients will also bring original ideas that don’t exist yet, In these cases, InIteration works with them to produce custom components and prototypes. Utilising the 3D printer farm for rapidly design iterations and efficiently test new features. We have built the InIteration print farm to be a scalable solution that can meet just about any demands efficiently.