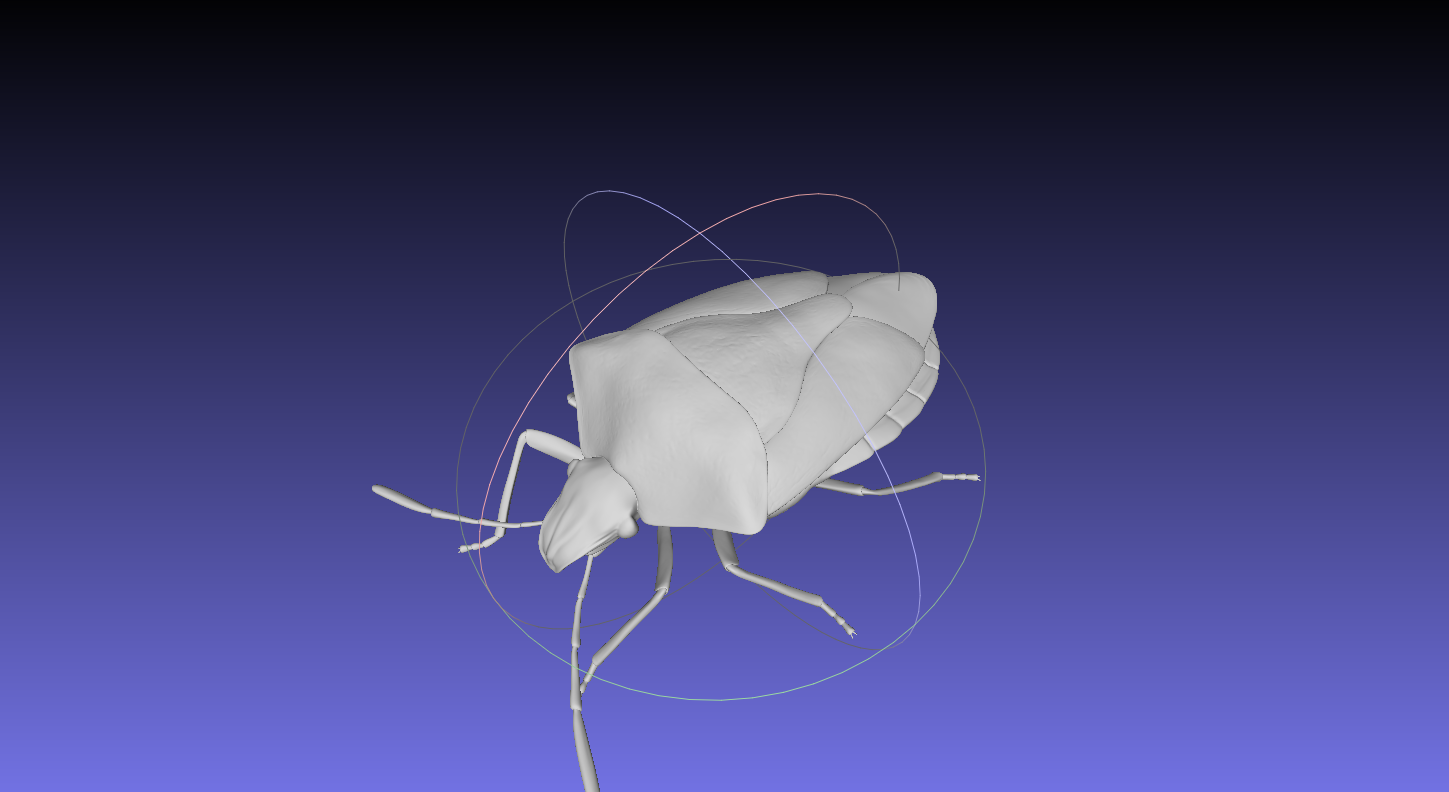

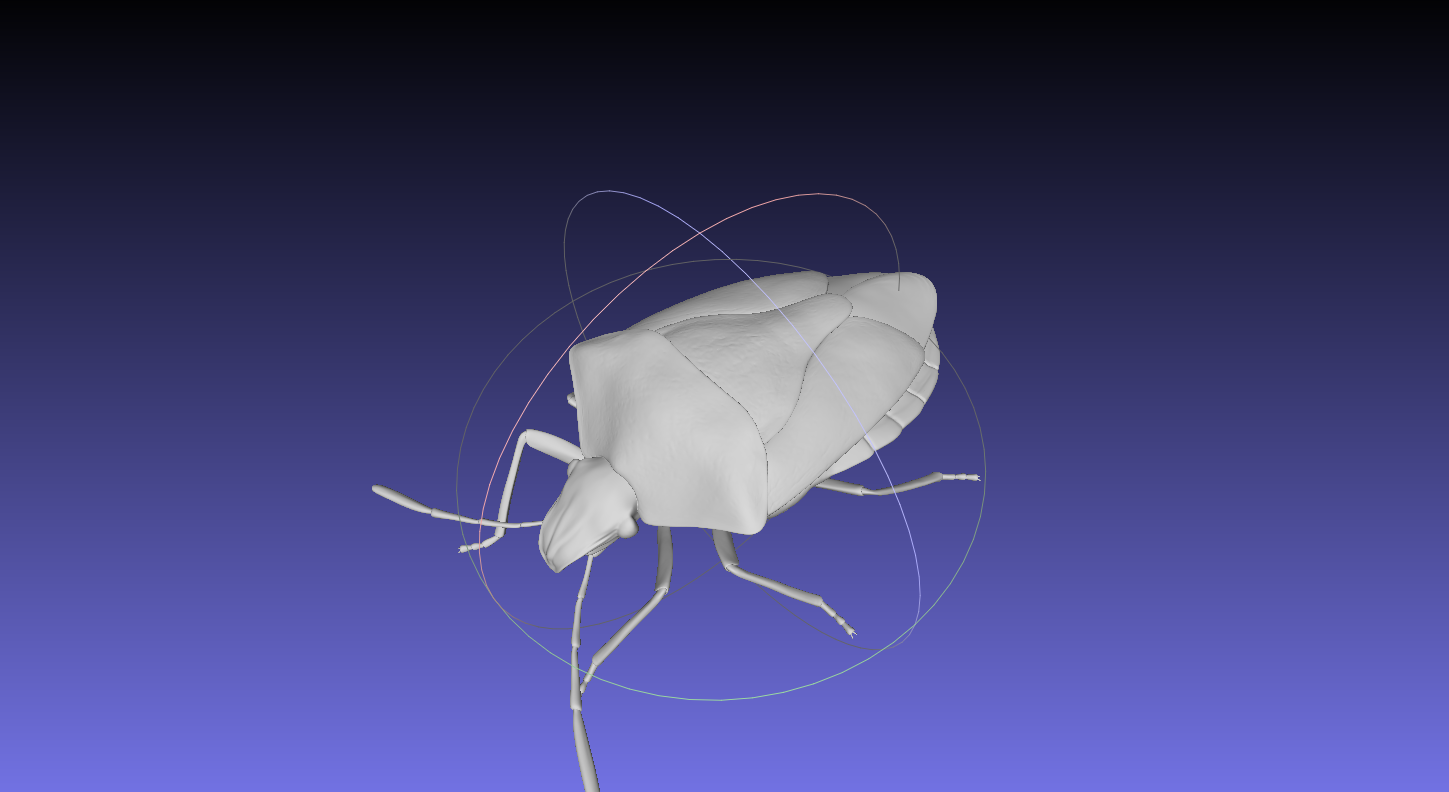

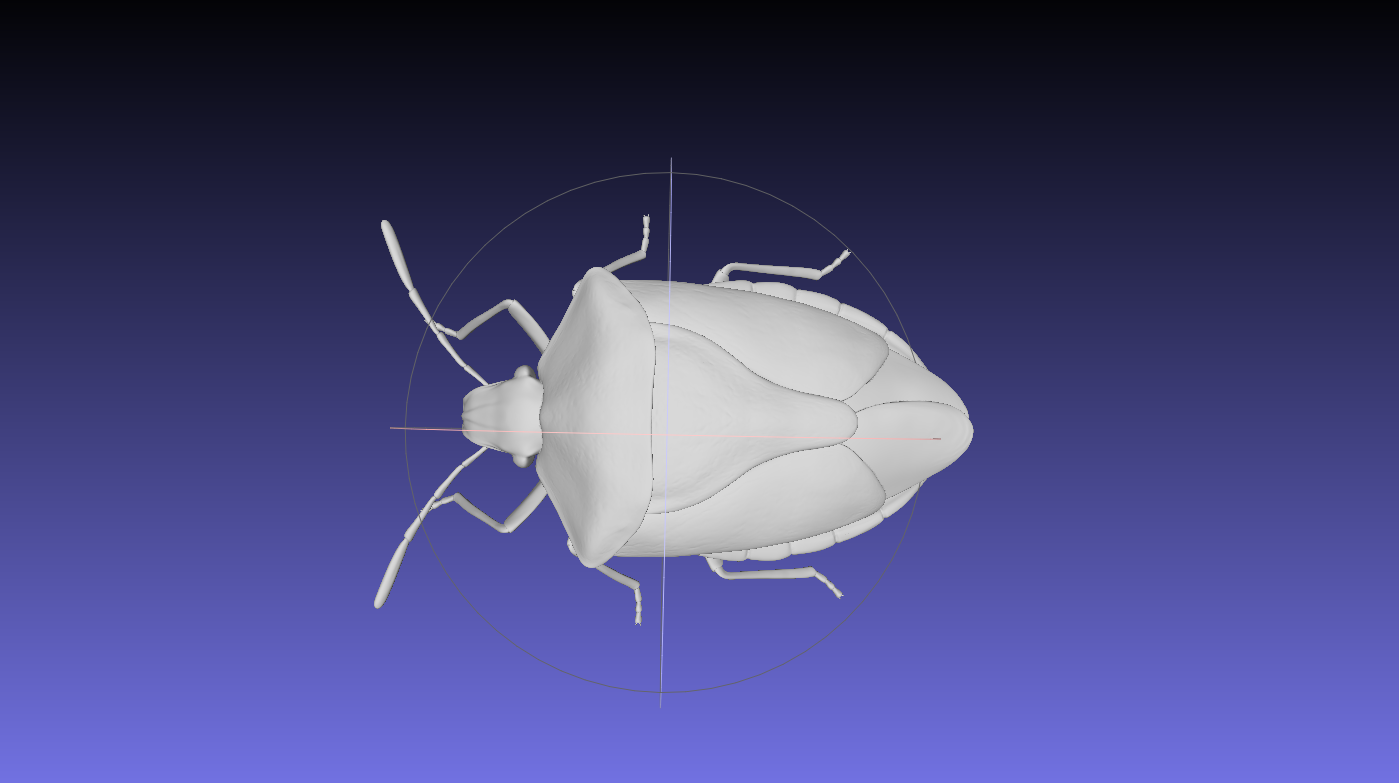

Replicating Bugs - BMSB & Khapra Beetle

Processes Involved:

Digital sculpting from references (Reverse engineering)

Resin 3D printing and assembly

FDM 3D printing during prototyping

Brush, ink, dye, and airbrush painting

Brief/Overview

Through multiple engagements with the Department of Agriculture, Fisheries and Forestry (DAFF); our team was assigned the task of producing large models depicting invasive bugs and beetles. These models were intended for display at roadshows and seminars, aimed at increasing awareness of the presence and potential risks posed by these invasive pests.

Approach

The recreation of the Brown marmorated stink bug (BMSB) and the Khapra Beetle used a different approach compared to Giant African Snail. As we were working from real preserved specimens, it was not possible to 3D scan either the bug or beetle. Therefore, they had to be digitally sculpted on the computer using both the preserved specimens and image references. Iterations of the designs were fabricated, and presented to scientists at DAFF Canberra throughout the project for review and refinement.

Outcome

The BMSB and Khapra beetle models were designed as an assembly and 3D printed in high detail resin. The parts were prepped, painted in batches, and then assembled. The legs were joined with aluminium wire for articulation. As part of the ongoing refinement process, we designed a small stand for the BMSB models.

All of the models were painted using airbrushing, and coated with a protective layer.

The resin used was translucent, which gave us the opportunity to play around with clear airbrushing dyes and explore how light diffused through the Khapra Beetle. The end result was an appearance similar to the original specimen and photos.

The BMSB was more challenging as the colours and dot pattern had to be scientifically accurate to distinguish its appearance from native stink bug species. Further post processing and painting was necessary to achieve the right level of detail requested.

These bug replication projects demonstrate how additive manufacturing can enhance production efficiency, reduce lead times, and support customisation - making 3D printing an indispensable tool in the modern manufacturing landscape.