Replicating Bugs - Giant African Snail

Processes Involved:

3D scanning

Resin 3D printing and assembly

Brush, ink, and airbrush painting

Brief/Overview

Over a series of separate engagements with the Department of Agriculture, Fisheries and Forestry (DAFF); InIteration was tasked to create large models of invasive bugs/beetles. The purpose of these models was to be displayed at roadshows and seminars. With the intention of raising awareness about the invasive pests and the risks they pose.

Approach

This project began with an ageing model of an Giant African Snail that was commissioned by the Department over 15 years ago. The model was deteriorating, and InIteration was asked to create a replica that was as scientifically accurate as possible to a real giant African snail. We decided that 3D scanning the original snail model would be the best path forward as this would not damage it, and could be completed in an afternoon.

Outcome

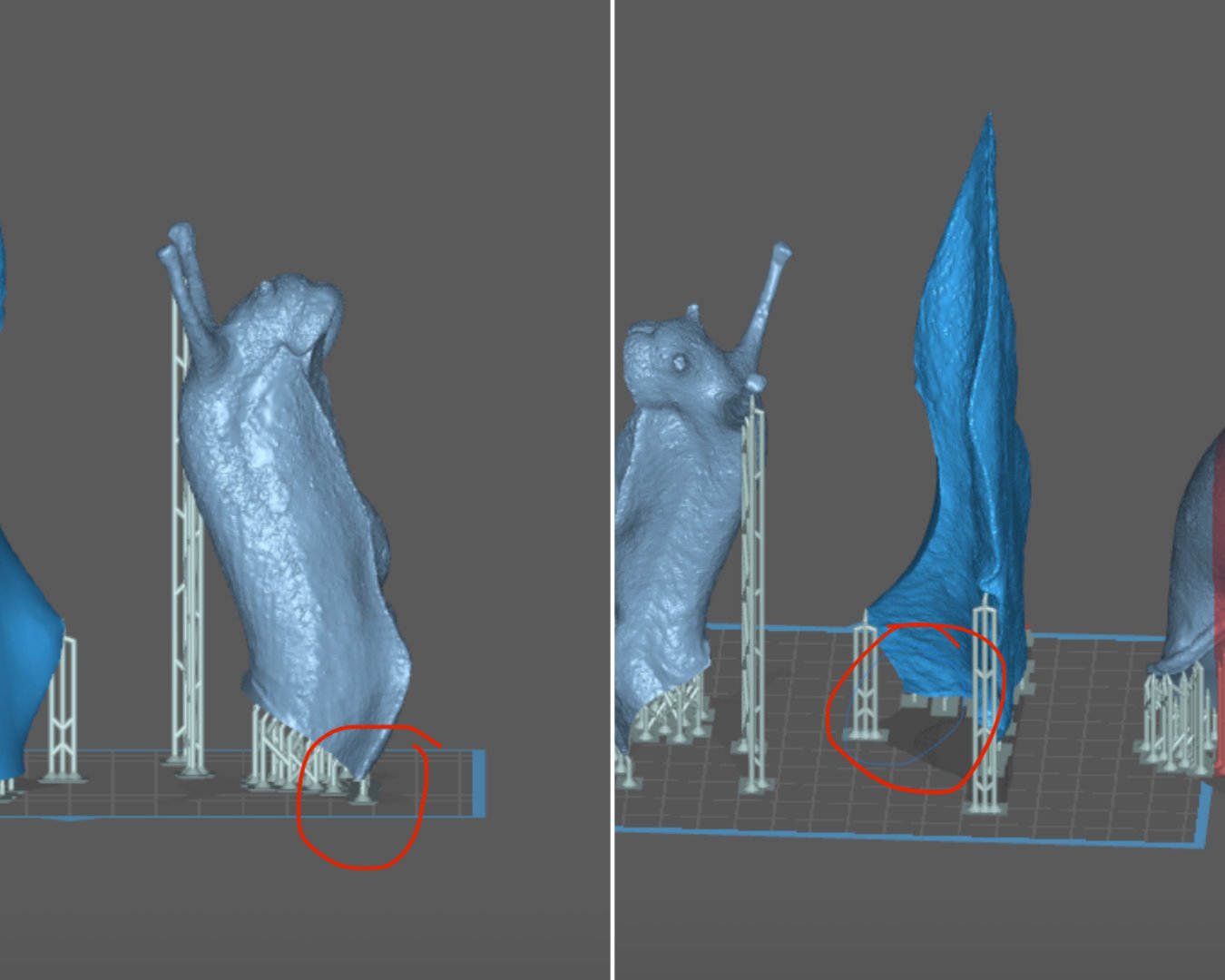

The existing snail model was 3D scanned with two different processes to accurately capture all angles: photogrammetry, and structured-light 3D scanning (Artec device). There were some challenges with lighting and the model’s glossy surface, but this was resolved by lightly coating it with a matt powder to reduce reflectiveness. After processing, the two scans were combined and corrected to preserve the details.

With the digital file complete, the new snail designs were 3D printed in high detail resin. These were fabricated in multiple parts, and glued together. Join lines were filled with putty, sanded, and then the whole resin print was spray painted with primer to be ready for painting.

The snails were painted using airbrushing, and coated with a gloss coat to give it a damp appearance. A number of different techniques were experimented with to achieve the correct shell pattern. DAFF were very pleased with the final model of the Giant African Snail and reordered more models, allowing us to continue to perfect the manufacturing process. 3D printing is an agile manufacturing process, we were able to improve the printing-to-painting process each time.

These bug replication projects showcase the remarkable capabilities of additive manufacturing.

It is an important tool in modern manufacturing, shortening lead times and facilitating deeper customisation.

Read about the next BUGS AND INSECTS we made and fabricated with DAFF.